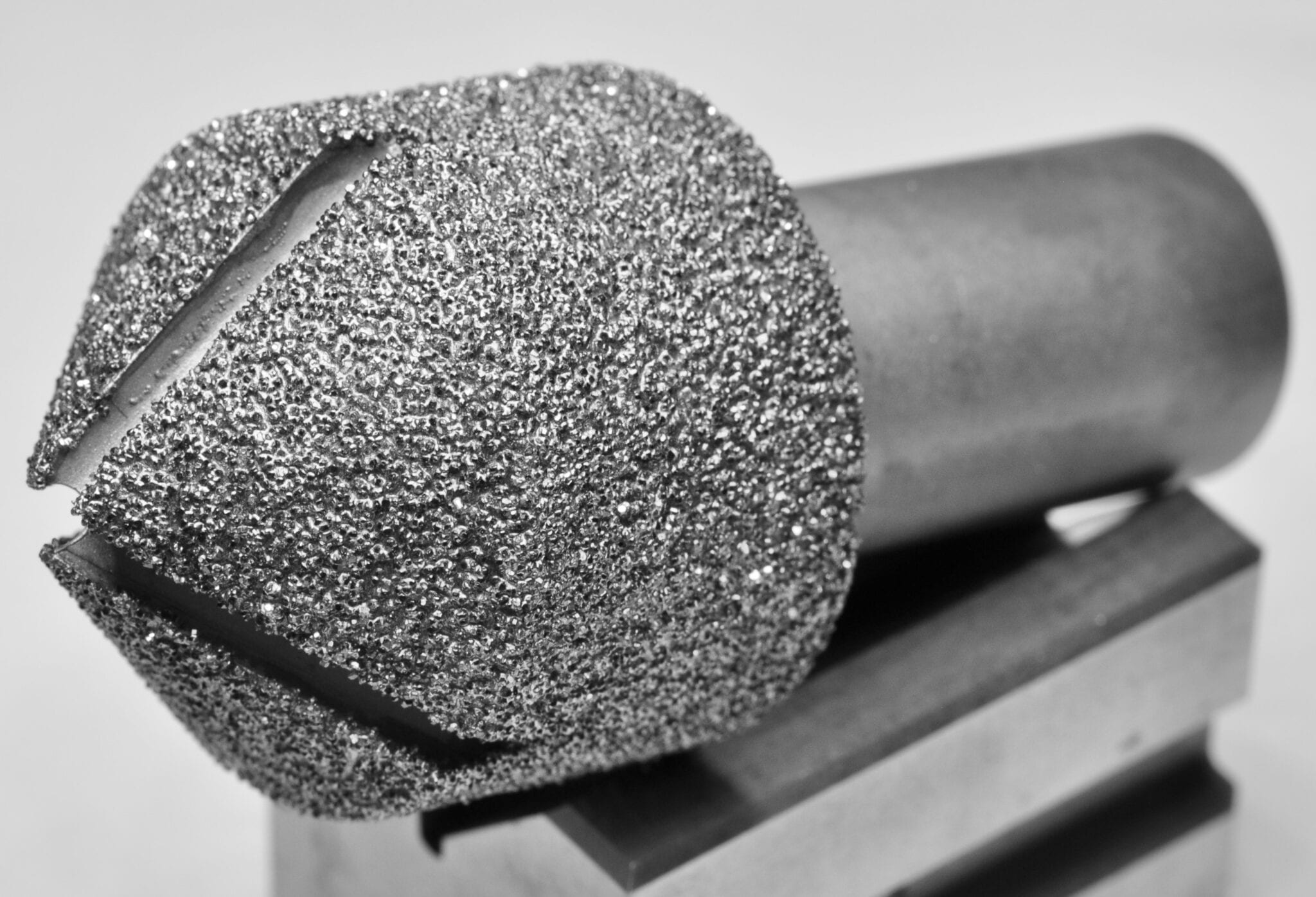

Diamond Grit Coating

Maximize the performance of your tools with Diamond Grit Coating, a synthetic diamond compound meticulously adhered to blanks such as wheels, blades, and core drills/hole saws.

Choose from versatile application methods including:

- Resin Bond

- Metal Bond

- Electroplating

- Brazed Plating

While primarily ideal for grinding tasks, grit coating can also excel in cutting applications in select scenarios, offering unmatched durability and precision for your machining operations.

Applications

Diamond grit coating finds wide-ranging applications across various industries and processes due to its exceptional hardness, wear resistance, and durability. Some common applications include:

- Grinding: Diamond grit-coated wheels, discs, and belts are extensively used for precision grinding operations in industries such as automotive, aerospace, tool manufacturing, and machining. They are employed for grinding hardened steels, ceramics, composites, and other hard materials with high precision and efficiency.

- Cutting: While primarily used for grinding, diamond grit-coated blades, saws, and drills can also be employed for cutting tasks in specific applications. They are used for cutting hard and abrasive materials such as concrete, ceramics, glass, and various composites in construction, fabrication, and manufacturing processes.

- Lapping and Polishing: Diamond grit-coated lapping plates and polishing pads are utilized for achieving high-precision surface finishes on a wide range of materials, including metals, ceramics, and optical components. They are commonly used in semiconductor manufacturing, optics, and precision engineering industries.

- Machining of Hard and Abrasive Materials: Diamond grit-coated tools are employed in machining operations involving hard and abrasive materials such as hardened steels, carbides, ceramics, and composite materials. They offer extended tool life, high material removal rates, and improved surface finishes compared to traditional tooling options.

- Drilling and Hole Making: Diamond grit-coated core drills, hole saws, and drilling bits are used for creating holes in hard and abrasive materials such as concrete, masonry, ceramics, and stone in construction, mining, and drilling operations.

- Medical and Dental Applications: Diamond grit-coated tools and instruments are used in medical and dental applications for cutting, grinding, and shaping hard materials such as bones, teeth, and dental ceramics with high precision and minimal tissue damage.